How durable and scratch-resistant is an acrylic stapler?

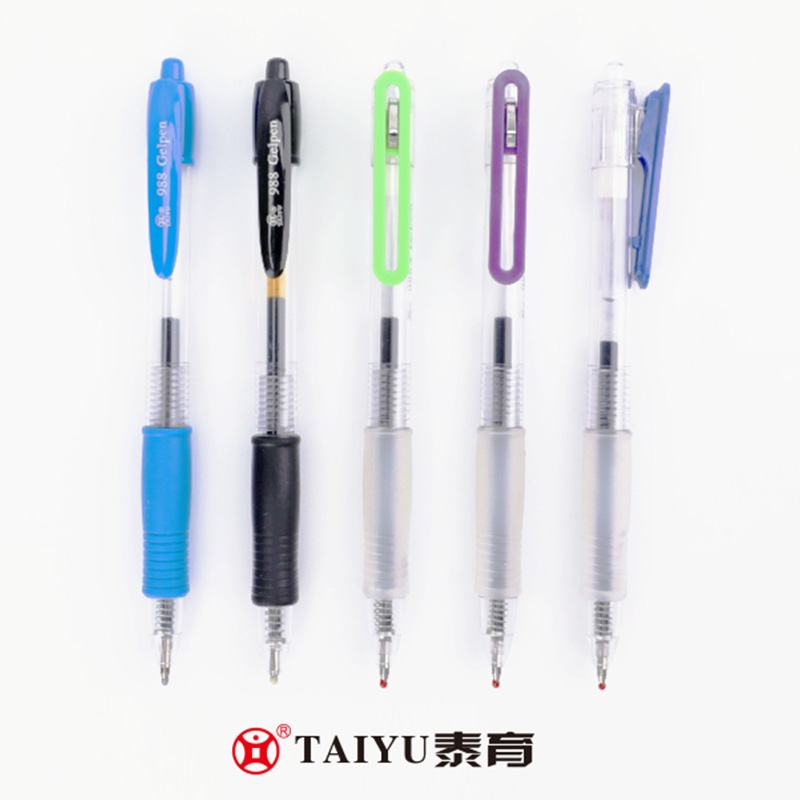

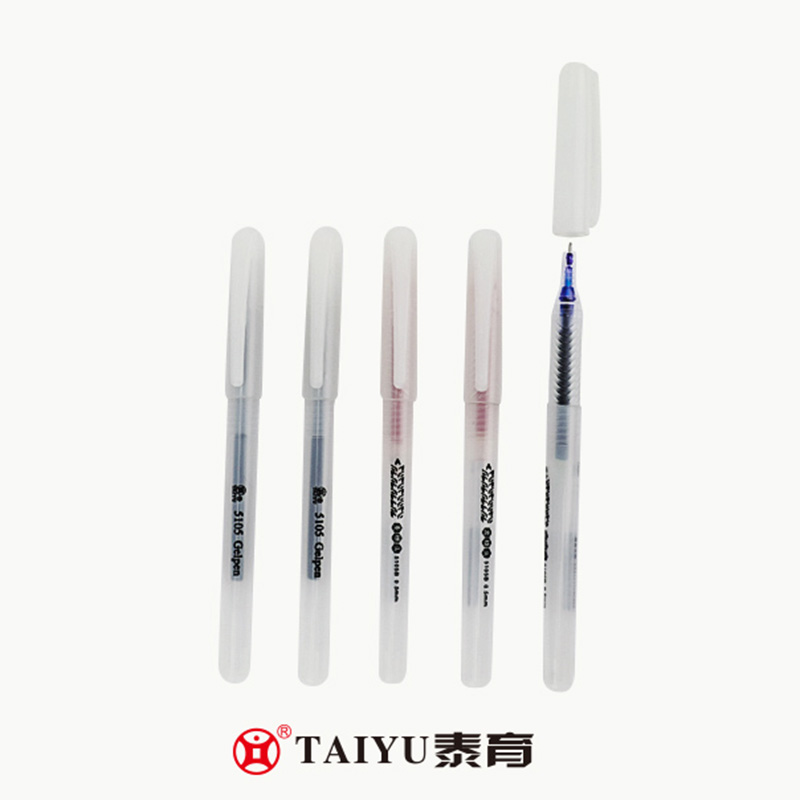

Acrylic staplers are made of acrylic, a common thermoplastic material widely used in transparent materials, decorations, displays, and office supplies. Due to its high transparency, good processability, and low cost, acrylic is often used in various office supplies such as staplers, pen holders, and file folders.

Physical Properties of Acrylic

Hardness and Abrasion Resistance: Acrylic has a Mohs hardness of approximately 2-3, making it a medium-hard material, lower than glass (5-6), but higher than common plastics such as ABS. While not as hard as metal or ceramic, acrylic has a smooth, scratch-resistant surface and exhibits a certain degree of scratch resistance.

Scratch Resistance: Acrylic's smooth surface is not easily scratched by sharp objects, but it can still be scratched by direct contact with sharp objects (such as knives and metal edges). However, acrylic has a certain degree of self-healing ability, and minor scratches can be restored through polishing or cleaning.

Weather Resistance and Chemical Stability: Acrylic has excellent weather resistance and is not easily affected by UV rays, temperature fluctuations, and chemical corrosion, making it suitable for long-term use. However, its acid and alkali resistance is average, and strong acids or bases may affect its surface.

Processability: Acrylic can be processed through injection molding, extrusion, and thermoforming, making it suitable for making complex-shaped components such as stapler casings and buttons.

Durability of Acrylic Staplers

Durability in Daily Use: Under normal use, acrylic staplers offer good durability. Due to their smooth, wear-resistant surface and simple structure, they are suitable for daily office or student use. However, prolonged use or frequent contact with sharp objects may cause scratches or wear.

Maintenance and Care: To extend the lifespan, it is recommended to clean the acrylic surface regularly and avoid contact with sharp tools or hard objects. If scratches do occur, they can be treated by polishing or using a special acrylic cleaner.

Methods for Improving Scratch Resistance

Surface Treatment: Surface hardening treatments (such as coatings and coatings) can significantly improve acrylic's scratch resistance. For example, surface hardening treatments (such as PVD coating) can increase acrylic's surface hardness to levels 4-5, approaching the hardness of glass.

Composite Applications: Using acrylic and polycarbonate composites can improve the material's impact resistance and scratch resistance while maintaining transparency and workability.

Protective Film Applications: Applying a protective film (such as PVC or PET film) to the acrylic surface effectively prevents scratches and abrasion, extending its service life.

Acrylic staplers are made of a material that offers a certain degree of durability and scratch resistance under normal use and proper maintenance. Although its hardness is moderate, its performance can be significantly enhanced through surface treatment, composite materials, or the application of protective films. However, acrylic's durability is still affected by its operating environment and maintenance methods. It is recommended to maintain proper care during daily use to extend its service life.

English

English 中文简体

中文简体 Español

Español